Identifying Electrical Issues In an Illuminated Sign

Electrical issues happen for a variety of reasons, and the same issues that caused problems for transformers, ballasts and lamps for decades, still impact new and retrofitted LED signs today. The good news is that LEDs and Power Supplies are much more reliable today than the days of lamps, ballasts and transformers. Newer LEDs and power supplies are engineered to tolerate more, so much so that sign companies these days have so few problems, that they are surprised when they DO get a service call. Here are a few notes our experts have gathered in regards to identifying electrical issues:

- LEDs are Not Invincible

- Factors that May Render an LED or Power Supply Failure

- Servicing a Failing Sign

- Quality LED Support Team

LEDs & Power Supplies are Not Invincible

LEDs & Power Supplies are not invincible. At times, they are susceptible to the impacts of amperage spikes, power draws, high voltages surges, fluctuations in power feed, excessive water and much, much more. Class 2 power supplies have specific safety shutoffs that are required by U.L. to be in place. So in some cases, even if an external electrical incident does not damage the power supply, its U.L.-required safety shutoff might have been triggered. These issues can trigger the safety features in power supplies resulting in flickering, strobing or dead signs.

Factors That May Render an LED or Power Supply Failure

At first, it may be easy to assume a product failure, however when working with electricity there are a lot of outside factors that can render an LED or Power Supply damaged or dead:

- Breaker issues

- Heat

- Inconsistent or ‘Dirty’ power

- Power or Amperage draws to the line

- Line issues

- Overloaded Circuits

- Power Grid issues

- or better yet, a combination of the above

There are ways in which the above topics can cause problems for signs. It can be challenging to determine the exact cause of an issue, simply because many of the above circumstances show the same symptoms (or even no symptoms at all!). And most often, these “electrical incidents” happen at the random moments. Think of a power draw, for example. A strong power draw can trigger a U.L. required shutoff on a power supply. When you service the sign, you test the input voltage and find that power is flowing fine. Similar to those random moments when the lights go off in your house or your office dim for 2-3 seconds and everything goes back to normal a few seconds later. If you were to test the voltage on your building 1 hour later, it would appear that nothing ever happened.

The reality is that each situation has a unique story and specifics that could require a variety of different questions to properly determine what the actual issue could be. Sometimes the evidence is obvious and sometimes not.

Servicing a Failing Sign

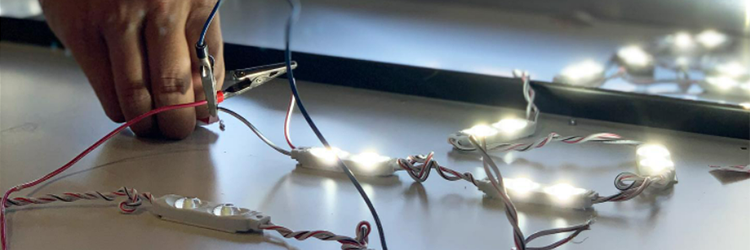

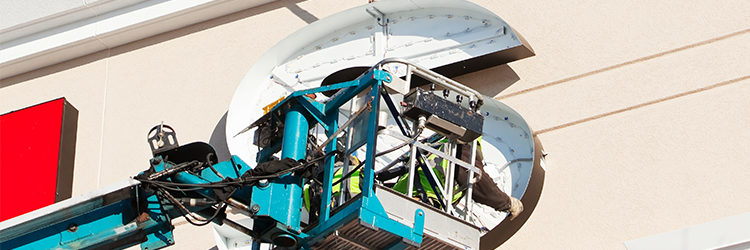

This McDonald’s sign was installed before the COVID-19 pandemic and the iconic golden arches were populated with HanleyLED PF4180W modules. Unfortunately, the end user noticed this portion had been out for a few weeks, but the power supplies appeared to be fully functional.

- Initial diagnosis described to the installer: "An environmental or external power ‘sting’ of some sort likely hit the system. The power supplies recycled and turned back on but not enough current was delivered to the LEDs. After that, some LEDs worked, some did not."

We understand that this initial possible explanation is hard to prove and may leave some installers skeptical. And for good reason, making service calls isn’t cheap! In this situation, while on site, the installer and customer watched multiple signs from a variety of businesses around them, including this one, flicker back and forth 5x in real time. MORE LEDS went out right before their eyes! When they initially tested the supply lines, the voltage readings were fine. But in that exact moment, a simple 10-30 second power disruption was enough to damage it. Turns out that to no fault of the business owner, the sign company or the LED manufacturer, did anything wrong. It ended up finding out it was a Power Grid issue. They were lucky to experience the incident with their own eyes, but most of the time, these incidents happen at any random moment.

Quality LED Support Team

In this example, diligent observation, photos, and communication with our LED support team helped determine the cause of this situation. At HanleyLED, quality control is our #1 priority and our most valuable asset. It is our mission to build your products with the highest quality components and workmanship. For that reason, our modules and power supplies are backed by the industry’s strongest warranty and most knowledgeable experts. If you have an electrical issue or an actual product failure our team is here to help by asking comprehensive questions and requesting photos like the examples above to provide you with the best solution and service possible.

Learn More

Want more tips and tricks? Learn how to reduce the risk of a service call Here!

Need a sign layout? Create your own Here!