Top 3 Reasons Why Polystyrene Is Used for Various Applications

Polystyrene is everywhere - and for good reason! When it comes to choosing which products to use for specific applications it benefits a printer to use a product that benefits them in multiple ways. Here are the top 3 reasons why polystyrene is a product of choice for many printers in 2023:

- Compatibility across multiple print platforms.

- Easily fabricated and very durable.

- Versatility of applications.

Compatibility Across Multiple Print Platform

Polystyrene is a great option for any print provider's setup. Duratex Polystyrene is manufactured in a controlled environment to ensure each sheet's surface is clean, smooth, and uniform. We also corona treat each sheet at a dyne level to where they will be compatible with multiple printing platforms. For instance, polystyrene can be used for Digital (wide format), screen, lithographic, and offset printing methods. Ultimately, Duratex Polystyrene is one substrate that works across all your production methods.

Easily Fabricated And Very Durable

Polystyrene has advantages over other products for a few reasons. The main reason being that it's a lightweight and flexible material, but also extremely durable. This in turn makes handling and installation less cumbersome and allows the product to hold up over time. Due to its closed cell structure, Duratex Polystyrene can even be used in short term outdoor applications or humid environments without the risk of warp like you would experience in other open cell plastics. Polystyrene's solid structure allows for the material to be easily fabricated with traditional cutting and finishing tools, which enables printers to produce dynamic and unique signage for a multitude of applications!

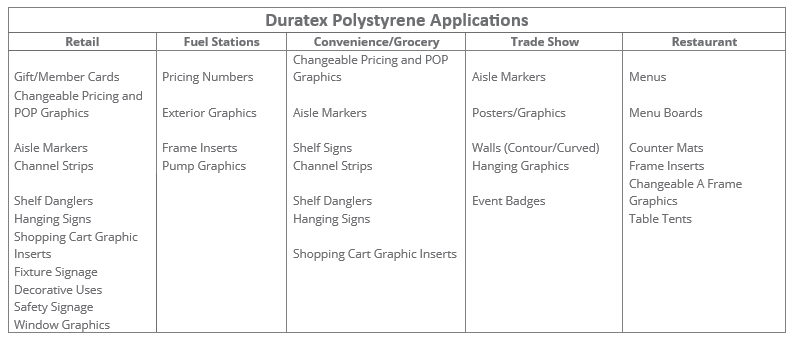

Versatility Of Applications

Polystyrene is a cost-effective substrate that can be manufactured in a wide range of thicknesses, sizes, and opacities, making it one of the most popular materials for printed graphics and signage. You will often see polystyrene in environments such as:

- Trade Shows

- Retail

- Restaurants

- Fuel stations

- Convenience centers

- and many more.

As stated above, polystyrene has low moisture absorption, making it a great fit for short term outdoor graphics. It is often used for exterior changeable signage such as promotional signs, menus, and price cards commonly seen in gas stations, home improvement stores, and garden centers. Polystyrene performs best in an environment that does not experience sudden large shifts in temperature and is recommended for shorter periods of outdoor exposure, up to 3 months.

*Without a UV Iadder, traditional polystyrene can yellow over time. If your application is to experience prolonged sun exposure, contact your Grimco representative for alternative polystyrene solutions.

Need a Custom Quote?

Contact our rigid substrate experts at Boards@grimco.com

If you have additional questions, please reach out to your local Grimco office and they will be happy to assist you and provide the answers you are looking for!