How To Fasten, Mount, and Hang iON PVC Signs

Interior hanging signs and mounted signage are common applications in the graphics space and iON PVC is a great substrate for multiple applications! Here are our recommendations for a successful install when working with iON PVC.

- Screwing, Nailing and Sign Installation with Posts

- Frame Fastening of Flat Sheets

- Hanging Signs

- Grain Direction

Screwing, Nailing and Sign Installation with Posts

As with most plastics, iON PVC will expand and contract with an increase or reduction in temperature. This material property is known as linear thermal expansion and contraction. It’s important to take this into consideration during the fabrication and installation of your iON PVC sign. Below are items to consider when screwing, nailing, and installing iON PVC with posts:

- Bolt holes should always be larger than the bolt shaft to allow for thermal expansion and contraction, thus eliminating the possible stress at bolt fixing points.

- Split timber posts are the best to use because the PVC is supported evenly on both sides. If steel or aluminum poles are used, nylon bolts and washers give the best results. In all cases, never skimp on the number of fixing points. Use at least three on the average-sized sign. They should be evenly spaced and away from the top and bottom edges.

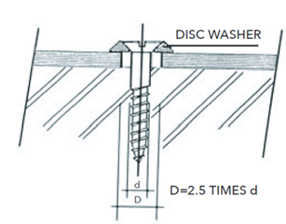

- When working with screwed joints the diameter of the hole or length of the slot should not be less than 2.5 times the shank diameter of the fastener. For best results, use oversized washers or grommets in combination with screws, this will spread the compressive load when bolts/nuts are tightened. Never over-tighten — this will only weaken the connection.

- Precise centering of the screws in holes and slots is essential to permit free movement of the sheet in all directions.

- While any type of nail or screw can be used to fasten iON PVC, we recommend using a nail gun or screw driving equipment to ensure a lasting hold.

Frame Fastening of Flat Sheets

Besides the inherent rigidity of Ion PVC, which is dependent on thickness, all possible exterior stresses, e.g., wind pressure, etc., must be taken into consideration in frame fastening. Dimensional changes due to thermal expansion (or contraction) must be taken into consideration by leaving sufficient clearance between the sheet edge and the frame. These are suspended attachment frames. Leave a space in the lower section, as well as in the side sections to allow for PVC expansion. One pin in the middle of the rail can keep the PVC centered in the frame.

Hanging Signs

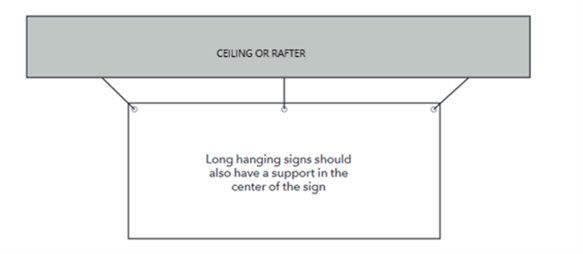

Thin gauges or large hanging signs may require additional support when using iON PVC for hanging signage. The addition of an aluminum or thick-walled plastic “C” channel across the top, bottom, or around the perimeter may be needed to alleviate any tendencies to warp. When the additions of supporting channels are not an option, the following suggestion may also be used to help prevent bowing. Holes should be located 2-1/2 times material thickness from edge. Point to point dimensions on the celling should be greater than point-to-point directions on Ion PVC.

Grain Direction

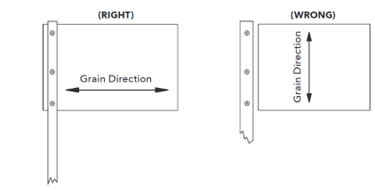

iON PVC is manufactured as an extruded foam PVC product with a directional grain running the entire length of the sheet. To allow your sign to “flex” with the wind pressure and ensure the best performance, the grain of the sheet should always be installed perpendicular to the fastening point.

Need More information?

We hope these recommendations gave you new ideas and help you complete a successful install for your next iON PVC project!

If you're for more information about fabricating and installing of iON PVC, Download our free fabrication Guide here!

Any additional questions, please reach out to Boards@grimco.com