Understanding the Differences between Cast and Extruded Acrylic

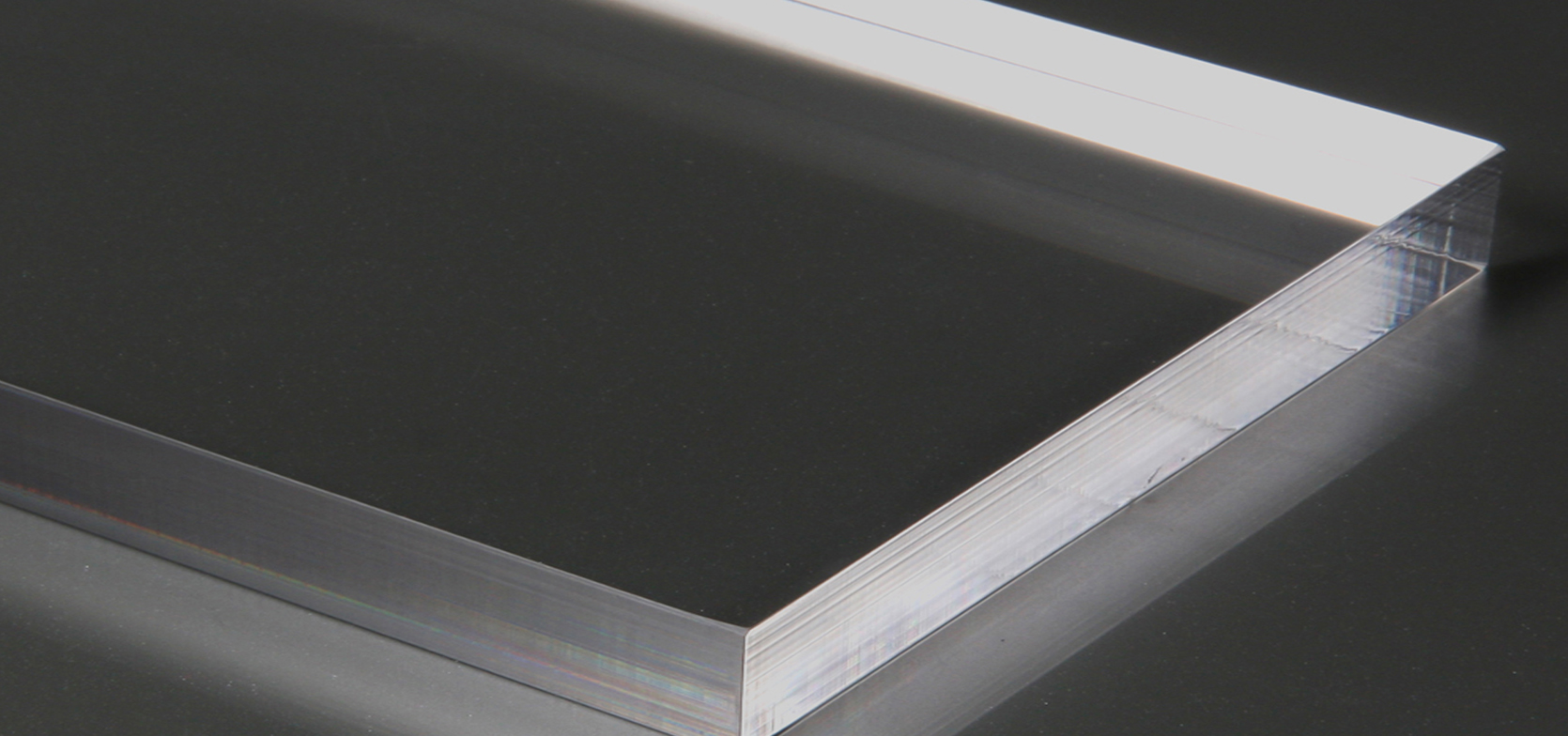

Acrylic is a versatile substrate, excellent for a wide range of applications. Such as trade show displays, building signs, POP retail graphics and so much more.

Do you know what your looking for? Many people who frequently use acrylic in the signage industry eventually ask themselves why they need to use cast acrylic vs extruded acrylic. So, let us break down why the physical, mechanical, and chemical properties make a difference.

- Cast Acrylic vs Extruded Acrylic

- Ideal Applications

- Cast Differentiating Qualities

- Common Applications

- Time & Money Saving

1. Cast Acrylic vs. Extruded Acrylic

Cast Acrylic: Cast acrylic is acrylic that is made by pouring and mixing liquid additive ingredients into a mold.

Extruded Acrylic: Extruded acrylic is a form of acrylic polymer materials produced by an extrusion method.

2. Ideal Applications

How would you use these types of applications?

Ideal Applications

- Laser Cutting

- Laser Engraving

- General Signage

- Cabinet Light Boxes

- POP Retail Graphics

- Dimensional Signage

- Building Signs

- Channel Letters

- Wayfinding Signs

Ideal Applications

- Pan formed Sign Faces

- Program jobs requiring consistent lighting

- Digital Prints

- Framing

- Cabinet Light Boxes

- POP Retail Graphics

- Dimensional Signage

- Building Signs

- Channel Letters

- Wayfinding Signs

3. Cast Differentiating Qualities

Thermal Stability

Cast acrylic has a great thermal stability standpoint. It is less likely to bend, chip or melt during routing, ultimately limiting the likelihood that it will clog your router drill bit. Extruded acrylic will soften as the temperature increases over 195 degrees F making it ideal for pan-formed signs because of its ability to mold easily. Additionally, easier routing leads to less clean-up. When routing cast acrylic, you can use a lower speed because of its high heat tolerance. This gives you a nice, clean edge right off the router table versus a rough edge, where polishing is needed to get rid of unwanted acrylic particles that may have melted themselves to the sheet. Also leading to less wear and tear on your router bits, so they will last longer and will not require a change so frequently.

Chemical Resistance

Cast acrylic offers the best chemical resistance in the acrylic category, especially when applying solvent cleaners or paints to the surface. Another factor to consider is outdoor exposure; due to cast withstanding a wide variety of chemical and outdoor exposure, it lends to be better for cleaning than extruded.

Tip: Generally, it is best practice to use an alcohol/water mixture when cleaning cast acrylic and paints with low or no VOC when painting on cast acrylic.

4. Common Applications

The cast acrylic sheets have a higher molecular weight which makes machining these sheets very easy to do. The chemical and outdoor resistance allows for a level of dependability that customers love. Extruded acrylic sheets have a low molecular weight and are excellent for general signage, illuminated signage, thermoforming, framing, and making displays. The design of both cast acrylic and extruded acrylic provides durability for your signage and consistent results.

Routing & Engraving

The thickness ranges of cast acrylic make it the perfect candidate for applications that require routing or engraving. The superior physical and mechanical properties alone, enable easier processing than an extruded sheet in this instance.

Displays & Framing

Extruded acrylic is perfect for display applications because it can handle chemicals for cluing and working with adhesives. The high-quality optical characteristic of extruded sheets makes it the ideal acrylic for framing applications.

Push Thru Letters

When creating a push thru letter for an illuminated sign application, it is generally best to use cast acrylic, especially on any acrylic that is ½” or greater in thickness. Doing so will give the end-user the cleanest look and create less labor for the shop fabricating the job.

5. Time & Money Saving

As mentioned, acrylic is a thermoplastic polymer material. Cast acrylic is thicker than other acrylic substrates you can choose. It is available in two different types based on the production process. This characteristic can ultimately save you time and money. It all comes down to processing.

Let us help you make the right choice for your business! Grimco offers a variety of acrylic options, with our most recent addition being Chemcast Cast Acrylic! Check out our Chemcast Cast Acrylic Sheets page to learn more! If you have any questions, see our Applications Assistant to ensure you find the right products to suit your needs or open a chat at the bottom of the page to talk to a Grimco representative.