3M™ IJ280 Cv4 vs 3M™ IJ180 Cv3

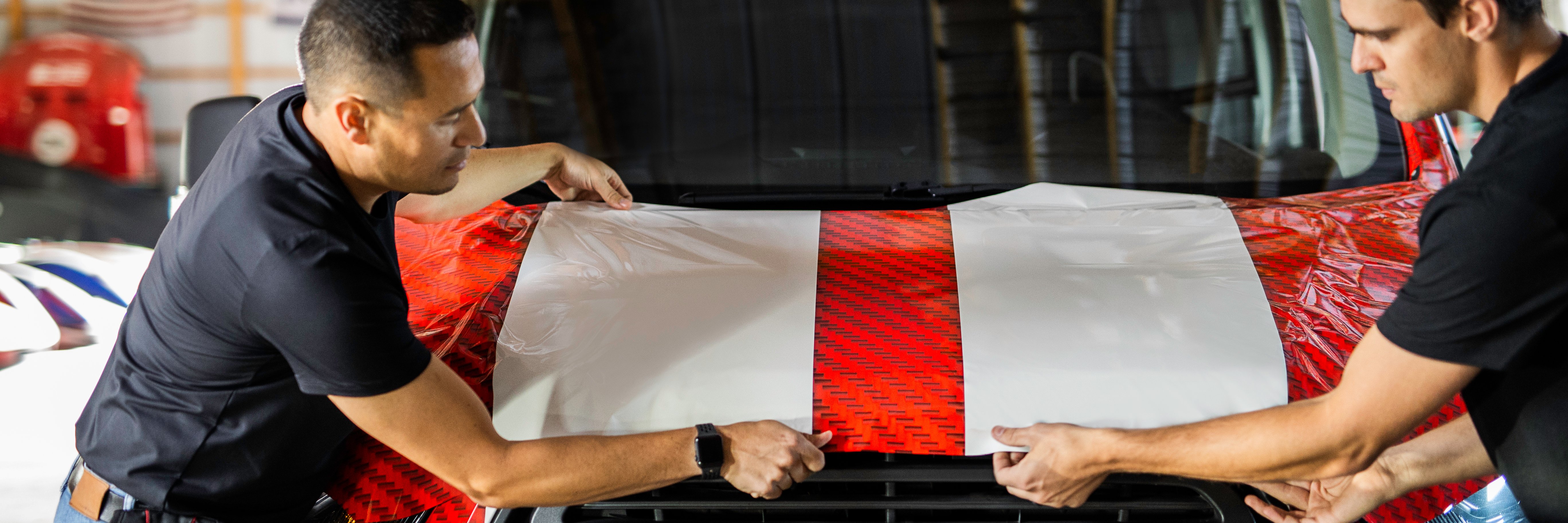

3M Print Wrap Film IJ280 is a best-in-class vehicle wrap designed for converters and installers who expect exceptional performance, print quality, and productivity. This print wrap film is highly conformable and offers excellent lifting resistance and is backed globally by the 3M MCS Warranty. With its proprietary adhesive and 3M Comply v4 Air Release, 3M Print Wrap Film IJ280 helps you get the job done quickly and get it done right the first time.

3M has introduced new technology with the IJ280 print film therefore, it is important to point out a couple of key differences to the popular 3M IJ180 Cv3 print wrap film.

- Conforms with less heat

- 3M Comply v4 Air Release

- Optimized initial tack, slide, and repositionability

- Reduced outgassing time

Conforms with less heat

The IJ280 film conforms more at room temperature, which means you can stretch and conform the graphic further with less heat. Any wrinkles will dissipate with little heat, allowing the film to conform with minimal stretch which allows for clean edges with no lifting. Even when heated, the film can be repositioned making it easy to fix mistakes.

3M Comply v4 Air Release

The new 3M Comply v4 Air Release pattern eliminates channel collapse, maximizes air flow, and finishes with a non-visible result. This new feature allows the installer to remove air bubbles effortlessly without snapping up the film if a squeegee pass is missed. IJ280 delivers exceptional performance and productivity which leads to faster installations with less work, giving the installer confidence they are delivering a high-quality wrap to their customer.

Optimized initial tack, slide, and repositionability

The tack of the new proprietary adhesive found on the IJ280 is low enough to easily slide or reposition the film meaning it won’t tack on the surface until you want it to. It is also high enough that you can trust the film to stay down. The combination of the new adhesive with 3M Controltac Adhesive technology enables excellent slide, no matter which printer platform the graphic was produced on. IJ280’s new adhesive has excellent holding power, ensuring that the film will stay down with no edge lifts and reducing the need for rework.

Reduced outgassing time

3M has introduced a new “solvent lock” feature which is a vapor barrier that is incorporated in the new IJ280 film which helps prevent reverse outgassing in instances where customers oversaturate the print with too much ink or laminate the print before the ink dries. With other films, such as 3M IJ180 Cv3, if a customer were to oversaturate the film with ink or laminate too early, the ink would outgas through the back of the film and effect the installation features and technologies in the adhesive. Because of the unique design of the 3M IJ280 Print Wrap Film, the recommended minimum of outgas time between printing and lamination has been reduced from 24 to 8 hours. As an installer, this means you can expect the same adhesive experience printed & unprinted and you won’t battle the “solvent effect”, even at a shorter outgas time.

Overall, when compared to 3M IJ180 Cv3 print wrap film, 3M Print Wrap Film IJ280 boasts 20% faster installation time and is proven to lift 2x less allowing you to deliver a quality wrap quickly and confidently.